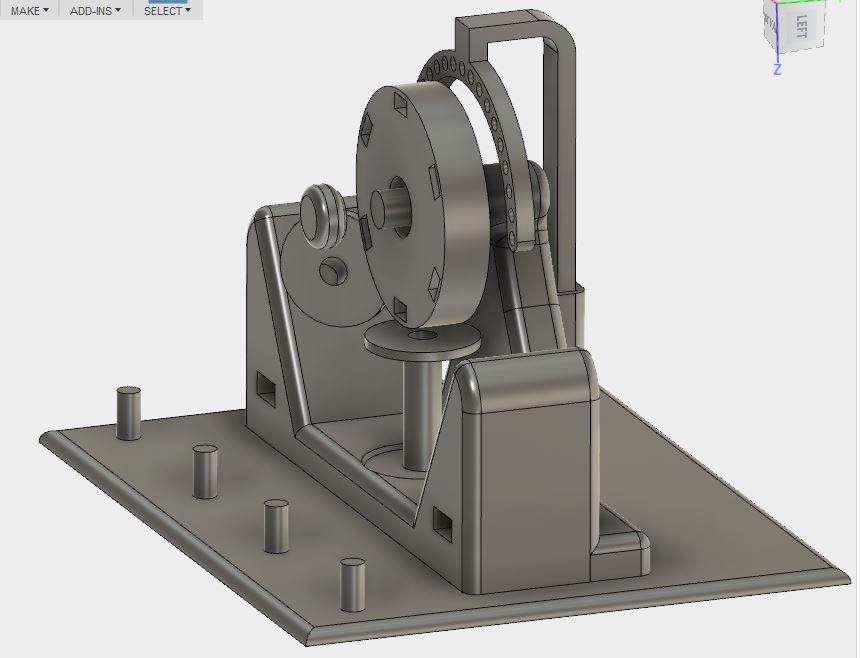

This is a very small build I am calling "The Toy".

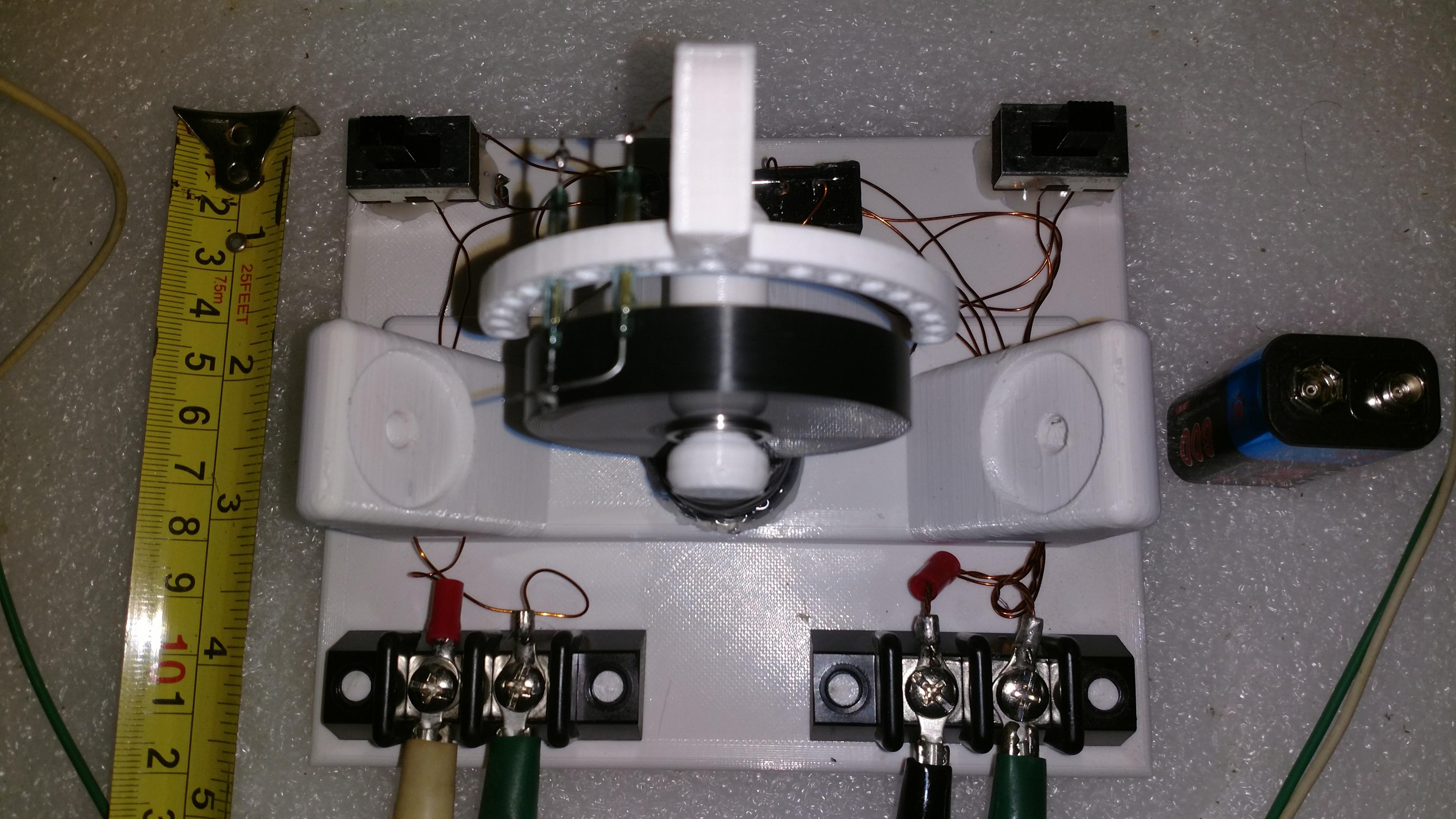

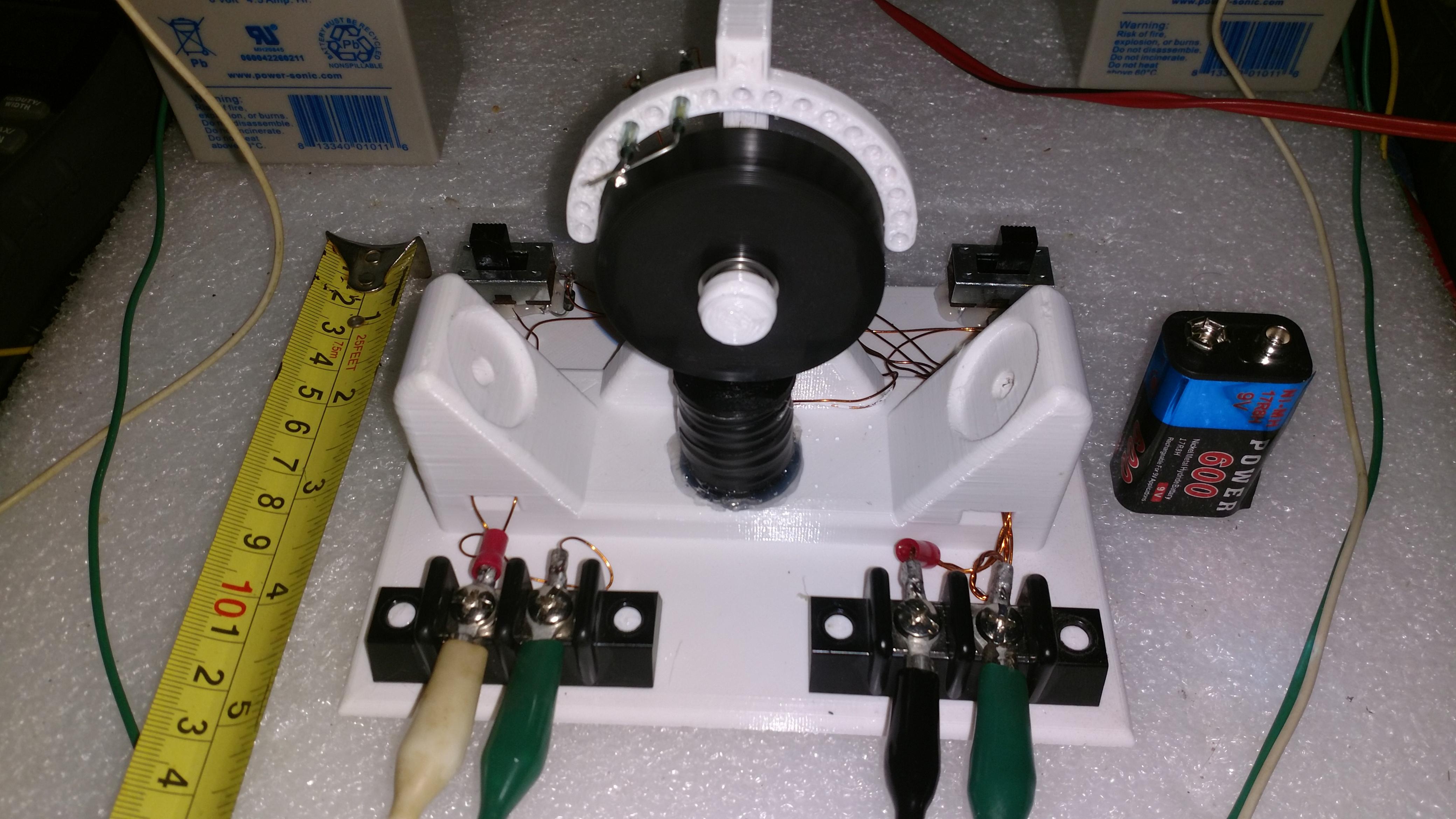

It is another 3D print model but simplified even more than the first one I posted. The parts for this are very minimal intentionally. It is very small having only a 50mm wheel. The deck is approximately 5 3/4 X 4 3/4 inch.

I have only run it a short time so far because I just finished building it last night but so far it works nicely. In mode one it is pulling about 150ma at 6V and around 300ma $ 6volt for common ground mode. I still need to do a lot of testing at different voltages but I started on the 6 volts 5AH that I have. I think it would run fine on soe 18650's or similar as well.

Anyway I will post some build files once I have tested a bit more with it.

It is another 3D print model but simplified even more than the first one I posted. The parts for this are very minimal intentionally. It is very small having only a 50mm wheel. The deck is approximately 5 3/4 X 4 3/4 inch.

I have only run it a short time so far because I just finished building it last night but so far it works nicely. In mode one it is pulling about 150ma at 6V and around 300ma $ 6volt for common ground mode. I still need to do a lot of testing at different voltages but I started on the 6 volts 5AH that I have. I think it would run fine on soe 18650's or similar as well.

Anyway I will post some build files once I have tested a bit more with it.

Comment