So I spoke too soon on the ABS. My first few things had no problems but now I am starting to see some warped prints. I am gong to have to put a box around the printer as Tom suggested (thanks Tom). It must be temperature because I know that when I first started printing it was hotter, the room the printer is in has no AC so it tends to follow the temps of outdoors to some degree. If it gets hotter outside so does the room or colder the same. Well it has gotten significantly colder the last few days and then the warping started.

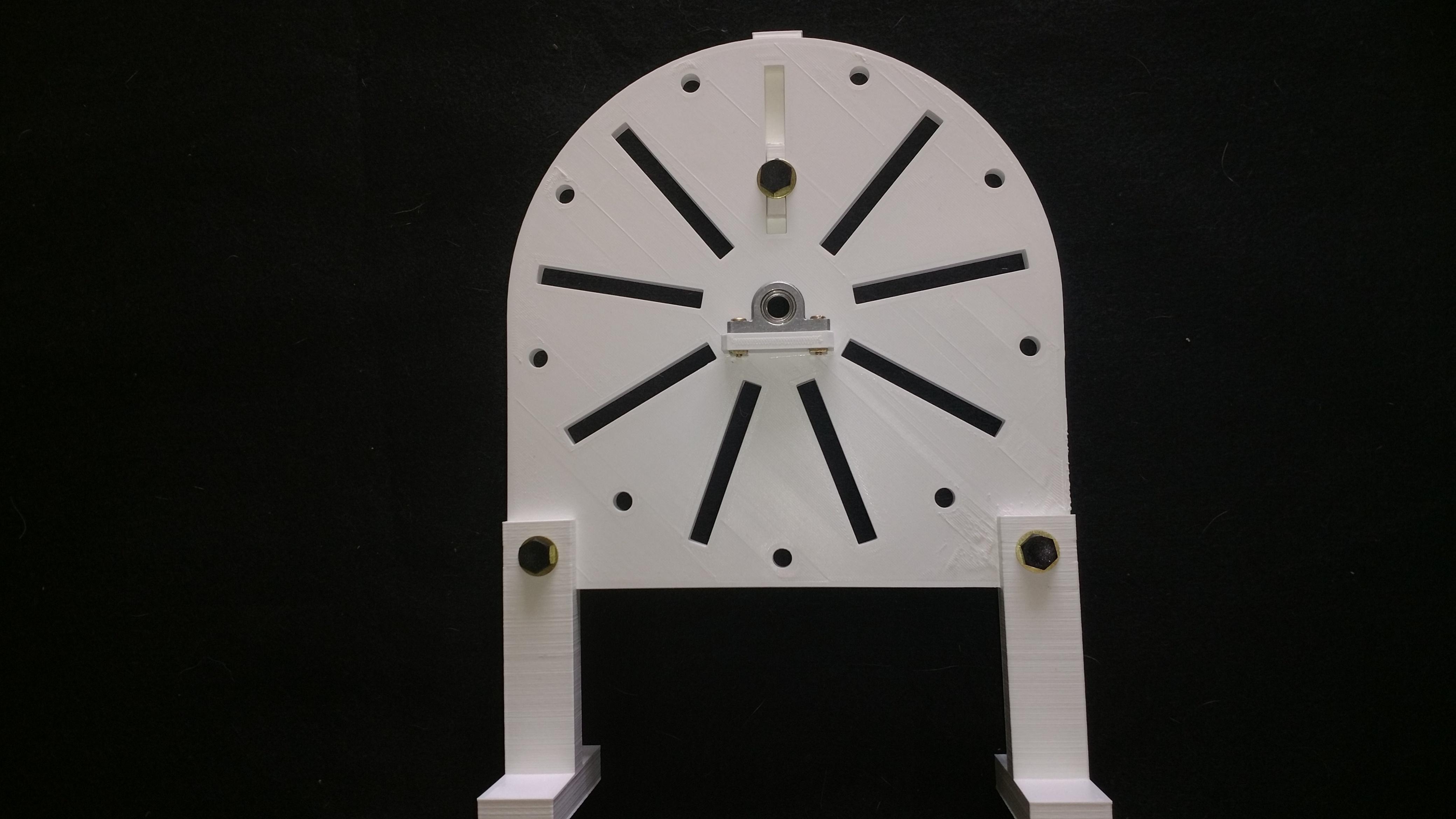

Over all things are going pretty good with the project. The holes all line up so far and have clearance for the bolts. They may be a hair too large but I think I will leave them so that later on if someone trys a print on a different model that maybe prints a little different tolerance than mine it should still work. By the time you tighten the bolts up it makes no difference really, there is a little play but not much adn when tightened up it is fine.

Over all things are going pretty good with the project. The holes all line up so far and have clearance for the bolts. They may be a hair too large but I think I will leave them so that later on if someone trys a print on a different model that maybe prints a little different tolerance than mine it should still work. By the time you tighten the bolts up it makes no difference really, there is a little play but not much adn when tightened up it is fine.

Comment